In the world of electronics, PCBA (Printed Circuit Board Assembly) is a term that frequently comes up when discussing the process of assembling and integrating electronic components onto a printed circuit board (PCB). Whether you’re a beginner in electronics or a seasoned professional, understanding the meaning of PCBA and the key components involved in its assembly is essential. In this article, we will explore what PCBA means and the role of LDR (Light Dependent Resistor) in PCBA manufacturing.

Table of Contents

What is PCBA?

PCBA, or Printed Circuit Board Assembly, is the process of placing and soldering electronic components onto a PCB to form a complete electronic circuit. Unlike the PCB, which is just a flat board with copper traces that connect the electrical components, the PCBA is the fully functional product used in all electronic devices.

Printed Circuit Board Assembly is crucial in the manufacturing of a wide range of products, from consumer electronics like smartphones and computers to industrial equipment and medical devices. The PCBA process involves several key steps:

- Solder Paste Application: A thin layer of solder paste is applied to the PCB, typically using a stencil. The paste is a mixture of flux and solder powder, which will help form strong electrical connections once the components are placed.

- Component Placement: Electronic components such as resistors, capacitors, microchips, and more are placed onto the PCB. This is usually done using automated machines like pick-and-place machines.

- Reflow Soldering: The assembly is passed through a reflow oven where the solder paste melts and solidifies, creating permanent electrical connections between the components and the PCB.

- Inspection and Testing: After soldering, the Printed Circuit Board Assembly undergoes inspection and testing to ensure the quality of the solder joints and that all components are functioning correctly. This can include AOI (Automated Optical Inspection), X-ray inspection, and functional testing.

- Final Assembly: The final steps of assembly may include additional tasks like adding connectors, enclosures, or other mechanical components that make the product ready for use.

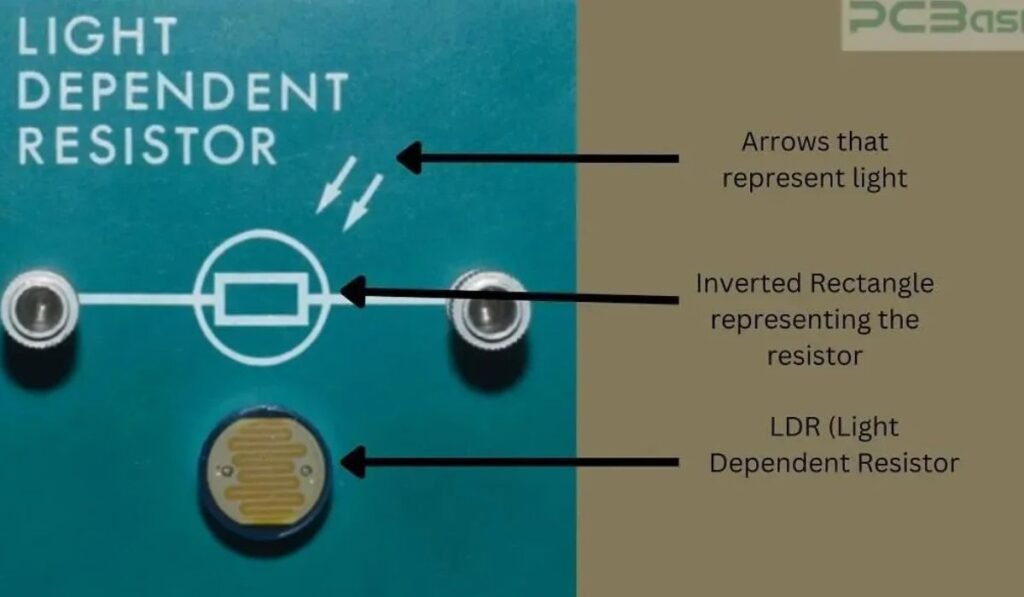

What is an LDR (Light Dependent Resistor)?

An LDR (Light Dependent Resistor) is a type of resistor whose resistance changes based on the amount of light it is exposed to. In the presence of light, the resistance of the LDR decreases, and in the absence of light, the resistance increases. This unique property makes the LDR an essential component in many electronic circuits, particularly those that require the detection of light levels.

LDRs are commonly used in applications such as:

- Automatic lighting systems: LDRs can control lights based on ambient light conditions, turning them on or off depending on the surrounding light levels.

- Light meters: They are used to measure the intensity of light in devices like cameras.

- Optical switching: LDRs can be part of circuits that switch between different modes based on light input.

The Role of LDR in PCBA Manufacturing

In PCBA manufacturing, LDRs are often included in assemblies for various applications. For example, they can be used in sensing and control circuits to adjust the operation of devices based on light conditions. In consumer electronics, LDRs are typically used in:

- Display brightness control: In devices such as smartphones and tablets, LDRs can automatically adjust the screen brightness based on ambient lighting.

- Solar-powered devices: LDRs are integral in solar-powered systems, where they help optimize energy usage by controlling the flow of power based on light levels.

During PCBA manufacturing, LDRs are integrated into the board assembly like any other component. They are placed onto the PCB during the component placement step, and their performance is verified during the inspection and testing phase. Given their light-sensitive properties, LDRs must be handled carefully to avoid exposure to high light levels during production, which can impact their functionality.

Why is Understanding PCBA and LDR Important?

Understanding PCBA and the role of components like LDRs is essential for both manufacturers and consumers. For manufacturers, it ensures the correct assembly of products and adherence to quality standards. For consumers, it helps in choosing the right products for specific applications and understanding how their devices function.

Key Takeaways:

- PCBA (Printed Circuit Board Assembly) is the process of assembling and soldering electronic components onto a PCB to create a fully functional circuit.

- LDR (Light Dependent Resistor) is a type of resistor whose resistance changes with light exposure, commonly used in light-sensing applications.

- In PCBA manufacturing, LDRs are integrated into circuits for various light-sensitive applications such as display control and solar-powered devices.

- Proper handling and testing of components like LDRs during the PCBA process are crucial for ensuring the quality and functionality of the final product.

By understanding the process of PCBA manufacturing and the role of essential components like LDRs, you can better appreciate the technology that powers the devices we use every day.